IntelliSpray 2

-

Great Value and High Versatility

What is IntelliSpray 2?

IntelliSpray 2 is a Pulse Nozzle System that maintains droplet size as the speed of the sprayer changes–This results in better coverage–Less drift as the speed of the sprayer increasesAvailable on all Nitro Sprayer Models

- Standard Features

-

Standard Features Include:

- Individual Nozzle Control

- Turn Compensation

- TeeJet Stacked Nozzle bodies (3 plus 1). The nozzle body has a 3-way turret and a single straight through nozzle normally used for high volume applications. The Pulse Width Modulation Valve can be installed on either the 3-way turret or the single – operators choice. You have the ability to spray with the IntelliSpray 2 system or convectional spraying system – operators’ choice

- Rate increase of up to 30% above target rate on 8 nozzles

- Electrical disconnects at lift arms so you can still easily remove the boom

- Instant on and off at nozzle bodies

- Can spray conventionally

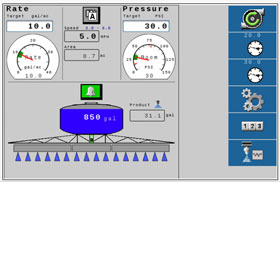

- How Does IntelliSpray 2 Work?

-

• IntelliSpray 2 maintains a constant droplet size by maintaining a constant spray pressure–All chemicals have a recommended droplet size to do a accurate job of coverage–Droplet size requirements are listed on the chemical label–Droplet size is one of the criteria you use to choose your spray tips• This is what normally happens on a conventional system–You choose a spray tip to match your needs – Lets say:• I want to spray at 14 mph• I would like to run at 35 psi• I would like to apply 15 gpa• I need a tip that will maintain a medium droplet size• As you speed up the pressure increases to maintain an accurate flow rate - Droplet size decrease or goes to a fine droplet size – Thus excessive drift occurs and you are off of the recommended droplet size• If you slow down the pressure decreases to maintain an accurate flow rate - Droplet size increase or goes to a course droplet size – You have less drift but again you are off of the recommended droplet sizeIntelliSpray 2 maintains a constant droplet size by maintaining a constant spray pressure– Whatever speed you are going 8 mph or 15 mph the pressure will remain constant at whatever pressure you chose– If the pressure stays constant the droplet size stays constant• Thus doing a much better job of spraying• Less susceptible to drift• Maintaining droplet size requirements from the chemical producer

• IntelliSpray 2 maintains a constant droplet size by maintaining a constant spray pressure–All chemicals have a recommended droplet size to do a accurate job of coverage–Droplet size requirements are listed on the chemical label–Droplet size is one of the criteria you use to choose your spray tips• This is what normally happens on a conventional system–You choose a spray tip to match your needs – Lets say:• I want to spray at 14 mph• I would like to run at 35 psi• I would like to apply 15 gpa• I need a tip that will maintain a medium droplet size• As you speed up the pressure increases to maintain an accurate flow rate - Droplet size decrease or goes to a fine droplet size – Thus excessive drift occurs and you are off of the recommended droplet size• If you slow down the pressure decreases to maintain an accurate flow rate - Droplet size increase or goes to a course droplet size – You have less drift but again you are off of the recommended droplet sizeIntelliSpray 2 maintains a constant droplet size by maintaining a constant spray pressure– Whatever speed you are going 8 mph or 15 mph the pressure will remain constant at whatever pressure you chose– If the pressure stays constant the droplet size stays constant• Thus doing a much better job of spraying• Less susceptible to drift• Maintaining droplet size requirements from the chemical producer - Turn Compensation

-

Turn compensation will control the output of the nozzles at different rates as you are turning

Turn compensation will control the output of the nozzles at different rates as you are turningExample:

If you are turning to the right with a 120 foot boom

•The left tip is going significantly faster than the right tip•The system will increase the nozzle out put on the left side of the boom and decrease the nozzle output on the right side for a more accurate application rate - Durability

-

IntelliSpray 2 has been tested for shock, vibration, impact and weather resistance in rugged terrain and extreme temperatures. Additionally, its Viton seals have had over 1,000 hours of testing to ensure system reliability. Intellispray 2 is also IP69K rated, meaning the NCV’s are pressure washer rated making it easier to clean. Severe-duty poppets now come standard, extending the operating life.

Specfications

- IntelliSpray Specifications

- IntelliSpray Specifications

-

- IntelliSpray Node

- Standard on all Nitro sprayers equipped with a Miller Precision Farming Base Kit

- Individual Nozzle Control - optional

- Individual nozzle control is optional on sprayers equipped with a Raven Viper 4+ field computer. Can be field installed with no hardware changes.

- Nozzle Solinoids

- There is one (1) nozzle Solenoid required per nozzle body assembly

- 10 Hertz

- Max amp draw 0.95 per solinoid

- 13.6 Nominal operating voltage

- Operating Pressure 0-80 psi

- Individual Adjustable Rate Nozzles

- Yes - You can adjust up to 8 nozzles individually

- Nozzle Bodies

The system uses TeeJet stacked nozzle body assemblies. The nozzle body has a 3-way turret and a single straight through nozzle normally used for high volume applications. The Pulse Width Modulation Valve can be installed on either the

3-way turret or the single – operators choice. You have the ability to spray with the IntelliSpray system or convectional spraying system – operators’ choice

- Nozzle Spacing

- IntelliVSpray can be ordered with either 15" or 20" nozzle spacing

- Instant ON/Off at Nozzle Bodies

- The IntelliSpray solenoid will provide instant on/off at the nozzle body. Conventional spraying will still have a lag time shutting off

- Turn Compensation

- Standard when spraying with IntelliSpray

- Maximum Application Rate

- 20 gallons per acre @ 15 mph. Higher volumes can be applied using the conventional spray nozzles.

- In Cab Diagnostics of Solinoids

- Standard