SprayView IV

SprayView IV

SprayView IV Precision Farming Kit is a member of the CNH Industrial line of field computers.

The kit includes: SprayView IV ISOBus field computer, SpraySteer™ navigation and a NH372 GPS receiver.

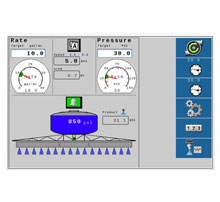

The SprayView IV is customizable, intuitive and easy to operate. You can run up to 6 screens on a single monitor. It is easily adaptable to other equipment on your farm. Monitor and record field performance operations.

- 10.4 inch touch screen display

- Fingertip adjustment of most spray functions including but not limited to: Rate Control, Section Control, IntelliSpray, Steering, Boom Leveling and Chemical Injection

- ISOBus virtual terminal

Telematics / PLM Connect™

PLM™ CONNECT is designed to keep information flowing between the equipment and the management of your business. It works on a cellular network and automatically jumps towers when your equipment is moving from field to field. Features include: vehicle/fleet management, vehicle/fleet monitoring, vehicle/fleet maintenance, vehicle/fleet status, wireless data transfer and much much more. The agronomic data belongs to the owner – neither CNH Industrial nor the dealer will have access to it.

SpraySteer™ Navigation

SpraySteer is a fully integrated CNH Industrial designed and developed Automatic Steering System. Available from the factory or as a retrofit package, the SpraySteer™ system maximizes productivity and efficiency to optimize your yields and to increase your profits. Matching DGPS or RTK Technology to fully integrated control, SpraySteer helps ensure parallel pass-to-pass accuracy of up to 1 inch. SpraySteer is the natural choice for precision work in even the most demanding conditions and it has been designed to dramatically enhance operator performance and comfort. Furthermore, this can be linked to Controlled Traffic Farming (CTF) applications. In line with CNH Industrials Open Strategy. CNH’s capability to utilize and export different competitive A-B guidance lines with SpraySteer allows maximum flexibility.

Headland Turning

The SpraySteer™ Navigation system can be upgrade (unlock code) for automated headland turns. Makes finding the proper reentry row automatic!