Spray Air Technology

-

The most precise application technology available

When coverage is critical and you need deep canopy penetration to kill the target pest - be it weed, disease, or insect - look no further than to Miller’s Spray-Air air boom technology.

The unique air nozzle spray system puts instantaneous control of droplet size, spray pattern, and the speed of the air blast spraying into the crop right at your fingertips. There is no other technology available that will give you coverage as good as this, with the lowest application rates possible.

Available on the Nitro 5000 & 6000 series and Condor GC series with spray widths up to 120 feet. Spray-Air air boom technology will improve your application efficiency and generate a superior return on your investment!

- How It Works

-

How the Spray-Air technology works

• The Air Nozzles, spaced every 10” along the air boom, atomizes the spray droplets using Dial-A-Drop™ technology. This creates the optimum-sized droplets that are not affected by speed and pressure changes, ensuring a uniform application over the entire field.

• The Air Nozzle blasts the spray droplets deep into the crop canopy, ensuring complete top-to-bottom leaf surface coverage. No other application technology can measure up to the total plant coverage from the Spray-Air nozzle.

• Because of the smaller controlled droplets and directed air blast, the Air Nozzle allows for a very efficient use of water, often in the range of 2 to 5 gallons per acre for herbicides, and generally from 5 to 10 GPA with fungicides.

- Droplet Size Management

-

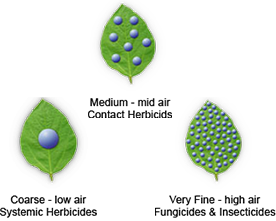

Droplet Size Management

Follow the ASAE Droplet Classification Standard with Dial-A-Drop™ technology.

- Benefits

-

Benefits of using Spray-Air technology*

• Maximize Productivity. The superior plant coverage from the use of the Air Shear Nozzle enables you to use only the minimum amount of herbicide required, and no more.

• Lowest Water Volumes. Use the lowest possible carrier volumes for herbicide, desiccant, insecticide, and especially fungicide applications. Spray from 2 to 10 gallons per acre.

• Fungicide Applications That Work. Simply stated, the Spray-Air technology is proven to be the best method to apply fungicides for superior disease control! Benefit from dense canopy penetration and total plant coverage with often only 5 to 10 gallons of water per acre!

• Application Versatility. Three application methods to choose from:

• Spray-Air Air Nozzle application to maximize coverage and efficiency

• Conventional flat fan nozzles for higher volume applications over 10 gallons per acre

• Use conventional nozzles + air blast from the Air Nozzle for classic Air Assist to maximize coverage in higher volume applications

• Environmental Stewardship. Spray-Air owners practice environmental stewardship by using only as much chemical and water as required, reducing soil and water carryover of crop protection products.

• Return on Investment. Operator surveys show $6 to $10 per acre in application cost savings

Specfications

- NITRO Spray-Air Booms

-

- Boom Construction

- Truss Style construction with individual wing tilt (wing tilt cylinders are equipped with accumulators).

- Boom Widths Available

-

- 90 / 60 ft.

- 100 / 60 ft.

- 120 / 73 ft.

- All booms are equipped with 10 section on/off valves

- Boom Lines

- 1 inch stainless steel pipe

- Nozzle Body Type

- Wilger stackable nozzles on boom pipes

- 4 psi non drip caps supplying Shear Guard Plus™ nozzle

- 10 psi non drip caps for conventional spraying

- Spray-Air patented Shear Guard Plus™ nozzle bodies mounted to air pipe

- Orifice Plates

- 0.034 Diameter Green Metering orifice plates are standard for Shear Guard Plus™ nozzles - other options available

- Nozzle Spacing

- Spray-Air - 10 inch nozzle centers starting on center

- Conventional - 20" nozzle centers starting on center

- Conventional option - 10 inch nozzle centers starting on center

- Air Fans

- Crary hydraulically driven fans (2) with controls and air tubes

- 6 inch air tubes run full width of boom

- Both fans feed the entire length of tube

- Raven Flow Meter

- RFM 15 flow meter

- UltraFlo Hydraulic System

- The UltraFlo hydraulic system option is required with the Spray-Air boom system

- Condor Spray-Air Booms

-

- Boom Construction

- Truss Style construction with individual wing tilt (wing tilt cylinders are equipped with accumulators).

- Boom Widths Available

- 90 / 60 ft.

- 103 / 60 ft.

- 120 / 73 ft.

- All booms are available with 5 or 10 section on/off valves

- Boom Lines

- 1 inch poly pipe

- Nozzle Body Type

- Wilger stackable nozzles on boom pipes

- 4 psi non drip caps supplying Shear Guard Plus™ nozzle on 10 inch centers

- 10 psi non drip caps for conventional spraying on 20 inch centers

- Spray-Air patented Shear Guard Plus™ nozzle bodies mounted to air pipe on 10 inch centers

- Orifice Plates

- 0.034 Diameter Green Metering orifice plates are standard for Shear Guard Plus™ nozzles - other options available

- Nozzle Spacing

- Spray-Air - 10 inch nozzle centers starting on center

- Conventional - 20" nozzle centers starting on center

- Conventional option - 10 inch nozzle centers starting on center

- Air Fans

- Crary hydraulically driven fans

- 1 fan on 90 and 103 foot booms

- 2 fans on 120 foot boom

- Fan controls and air tubes

- 6 inch air tubes run full width of boom

- Raven Flow Meter

- RFM 15 flow meter

- Hydraulic System

- 90 and 103 foot booms

- Load sensing hydraulic pump, engine driven, oil cooler and completing hydraulic system parts

- Load sensing hydraulic pumps (2), transmission driven, oil cooler and completing hydraulic system parts